Heavy-duty wire cutting machine tool breaks through the processing difficulties of aviation fuel pump flow plate

In the aerospace industry, every detail is crucial. Whether it is the pursuit of extreme performance or ensuring absolute safety, technological innovation has always been the core driving force of the industry's development. Today, we will explore a little-known technical application - the manufacturing process of complex flow plates inside fuel pumps in aerospace fuel systems, and the key role of large-scale heavy-duty wire cutting machines in this process.

Product Analysis: Uncovering the Precision Components of Aerospace Fuel Systems

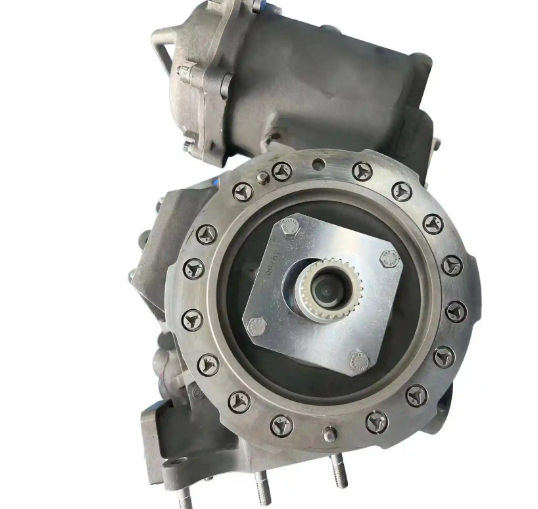

In the aerospace fuel system, the fuel pump is the heart of the system, and the design and manufacture of its internal structure are directly related to the efficiency and safety of the entire system. In particular, the design of the complex flow plate inside the fuel pump not only needs to ensure that the fuel can flow efficiently and stably, but also needs to withstand extreme temperature and pressure changes. This requires highly precise geometry and surface finish of the manifold to reduce drag and avoid any factors that could cause failure.

The use of large-scale heavy-duty wire cutting machines for the processing of manifold plates can achieve accurate replication of complex shapes while maintaining extremely high dimensional accuracy and surface quality. According to experimental data, after using this technology, the flow loss of the flow channel plate was reduced by 15%, which significantly improved the working efficiency of the fuel pump.

Processing Difficulties: Challenges and Coping Strategies

Although large heavy-duty wire cutting machines provide strong support for the manufacture of manifolds, the process is still full of challenges. First, the choice of materials is crucial. Since manifolds need to withstand high temperature and high pressure environments, they are usually made of high-strength alloys or special metals, which places higher demands on the cutting capabilities of machine tools. Secondly, in actual operation, how to control the cutting speed and current density to avoid deformation or cracking of the material due to overheating is a key point that requires fine adjustment.

In addition, considering that each model of aerospace fuel system has its own uniqueness, the design of the manifold plate will also be different, which means that each production needs to adjust and optimize parameters according to specific circumstances. This not only tests the professional skills of technicians, but also challenges the flexibility and adaptability of machine tools.

Summary and Outlook: Zhikai CNC, a leader in technological innovation

In this era of pursuit of excellence, "innovation" is not just a slogan, but also a driving force for the industry to move forward. For the manufacture of complex flow plates inside fuel pumps in aerospace fuel systems, choosing the right processing method is the key to success. As we can see, large-scale heavy-duty wire cutting machines have played an important role in improving product quality with their incomparable advantages.

However, the real victory lies not only in having advanced equipment, but also in the strong R&D strength and perfect service system behind it. Zhikai CNC is well aware of this and always adheres to customer demand-oriented, continuously increases R&D investment, and is committed to providing the most cutting-edge solutions. At the same time, we have built a professional after-sales service network covering the whole country and even the world to ensure that every user can get timely and effective support.

"Innovation drives the future, service wins trust", Zhikai CNC is not only your ideal partner in the field of aerospace fuel system and other parts cutting, but also your trustworthy strong backing. Let us work together to open up a more brilliant tomorrow with wisdom and technology. "Be good at heart and go far", let every cooperation become a solid step towards success.

With strong technical strength and strict quality management, Zhikai's medium-speed wire cutting machine tools have become the first choice for many manufacturing companies, such as construction equipment: wear-resistant parts of concrete pumping systems, chemical industry: corrosion-resistant parts in reactors, printing machinery: precision parts of offset printing machine ink roller adjustment devices, and intelligent security systems: customized production of video surveillance camera mounting bases. Advanced CNC systems and precision processes ensure that the machine tools run smoothly and with low errors; the full after-sales service allows customers in Minxian, Weiyuan, Longxi, Zhangxian, Anding District, Tongwei, and Lintao to experience meticulous support. Zhikai is willing to work with you to create efficient production and a better future. In addition, in order to help everyone better understand the relevant knowledge of medium-speed wire cutting machines, we will soon launch relevant popular science articles such as DK7735 simple metal wire cutting machine, 2-meter advanced wire cutting equipment, C-type seven-axis machine wire cutting, 2.5-meter small wire cutting machine, DK7740 wire cutting machine, small new wire cutting machine, 7740 precision wire cutting machine, etc. Everyone is welcome to visit and obtain relevant solutions.

If you have any needs, please contact Zhikai : 18013131588