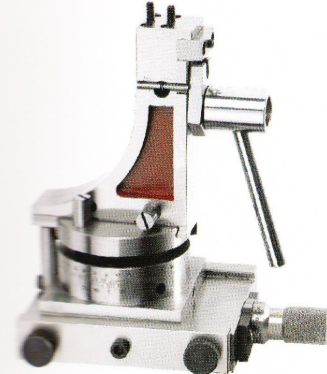

Precision parts of grinding wheel dresser: CNC grinding machine and large split wire EDM processing

If CNC grinders are the "craftsman's hands" of modern manufacturing, then the grinding wheel dresser is undoubtedly the "most delicate fingertip" of this hand. The manufacturing of its precision parts directly affects the machining accuracy and surface quality of the grinder. In the pursuit of ultimate precision, large-scale split wire EDM processing technology is playing an increasingly important role. Are you curious about how this seemingly complex processing technology helps manufacture precision parts of grinding wheel dressers? Today, we will uncover the "mystery" of manufacturing precision parts of grinding wheel dressers and explore the core advantages of large-scale split wire EDM processing technology.

1. The "heart" and "fingertips" of CNC grinding machines

As the core equipment of modern manufacturing industry, the processing accuracy and efficiency of CNC grinders directly affect the quality of products. The grinding wheel dresser, as a key component of CNC grinders, is responsible for the precision dressing of the grinding wheel to ensure that it always maintains the best cutting state. The precision parts of the grinding wheel dresser, such as the diamond pen holder, dressing arm, fine-tuning mechanism, etc., require the manufacturing accuracy to reach the micron level, with complex shapes and high material hardness, which is difficult to meet with traditional processing methods. The emergence of large-scale split wire EDM processing technology provides a new idea for solving this problem.

2. Product analysis of case customers: Application of Zhikai CNC large split wire EDM

In the manufacturing process of precision parts of grinding wheel dressers, Zhikai CNC's large split wire EDM plays an important role. Taking the diamond pen holder as an example, its material is usually cemented carbide, which has high hardness and great brittleness, and traditional processing methods are prone to cracks and deformation. Zhikai CNC's large split wire EDM machine adopts advanced pulse power supply technology and precision control system, which can achieve high-precision and high-efficiency cutting processing.

A customer's production manager said: Zhikai CNC's large split wire EDM machine has solved the problem of machining precision parts of grinding wheel dressers for us. Its machining accuracy and efficiency far exceeded our expectations, helping us significantly improve product quality and production efficiency and enhance market competitiveness. By adopting Zhikai CNC's equipment, our product qualification rate has increased from 95% to 99.8%, production efficiency has increased by more than 40%, and the processing surface quality has also been significantly improved.

3. Processing difficulties and Zhikai CNC's solutions

There are many processing difficulties in the manufacturing process of precision parts of grinding wheel dressers:

Cutting of high-hardness materials: The precision parts of grinding wheel dressers are usually made of high-hardness materials such as cemented carbide, and traditional processing methods are difficult to achieve high-precision cutting.

Processing of complex shapes: The precision parts of the grinding wheel dresser have complex shapes, such as the spiral groove of the fine-tuning mechanism, and traditional processing methods are difficult to ensure accuracy.

Micron-level processing accuracy: The processing accuracy of the precision parts of the grinding wheel dresser is required to reach the micron level, which places extremely high demands on the accuracy and stability of the processing equipment.

Zhikai CNC's large split wire EDM machine provides an effective solution to the above difficulties:

High-precision cutting: Using advanced pulse power technology and precision control system to achieve micron-level processing accuracy.

Complex shape processing capability: Equipped with a multi-axis linkage control system, it is capable of processing parts of various complex shapes.

High-efficiency processing: optimize processing parameters, improve processing efficiency, and shorten processing cycle.

Stable machining process: High-rigidity machine tool structure and precision transmission system are used to ensure the stability of the machining process.

4. Summary: Zhikai CNC - a reliable partner for precision manufacturing of CNC grinders

The manufacturing of precision parts for grinding wheel dressers is a major challenge facing the CNC grinding machine industry. Large-scale split wire EDM processing technology, with its advantages of high precision, high efficiency, and complex shape processing capabilities, has become an ideal choice to solve this problem.

"Smart manufacturing precision, leading the future." Zhikai CNC has always been committed to the research and development of advanced EDM wire cutting technology to provide more precise and efficient processing solutions for the CNC grinding machine industry. In addition to the precision parts of the grinding wheel dresser, Zhikai CNC's large split EDM wire cutting machine processing technology is also widely used in the manufacturing of other precision parts in CNC grinding machines, such as spindles, lead screws, guide rails, etc.

Zhikai CNC not only has a strong R&D team, constantly innovates and improves product performance, but also pays more attention to improving the after-sales service system to provide customers with timely and professional technical support. We believe that only by truly understanding customer needs can we provide more considerate services and become a trustworthy partner for customers.

Choose Zhikai CNC, choose precision and trust! Let us contribute to the high-quality development of the CNC grinding machine industry together!

If you have any needs, please contact Zhikai: 18013131588