The internal contact spring of the smart grid circuit breaker is precisely processed by super large machine tools

As smart grid technology continues to advance, how to improve the manufacturing accuracy and efficiency of key components such as the contact spring inside the circuit breaker has become the focus of the industry. These seemingly insignificant small parts play a vital role in ensuring the stable operation of the power system. Today, we will explore in depth the application of ultra-large multi-axis cutting machine tools in this field and the challenges they face.

Product analysis: Components that require high-precision processing in smart grid equipment

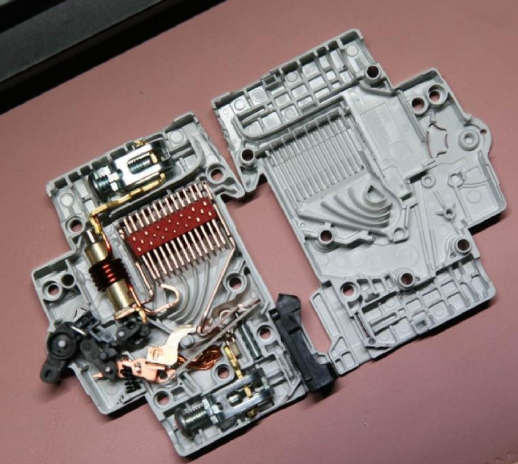

One of the core components of smart grid equipment, the internal contact spring of the circuit breaker, has extremely high requirements for material strength, elastic modulus and surface finish. This type of spring not only needs to withstand frequent mechanical stress, but also needs to ensure stable electrical performance during long-term use. Therefore, in the production process, it is often necessary to use ultra-large multi-axis cutting machine tools for precision processing.

Take a customer for example, they introduced a super-large multi-axis cutting machine tool to achieve precise control of the complex geometric shape of the contact spring inside the circuit breaker. According to the feedback data, the optimized production process increased the service life of the spring by 20%, while reducing the rate of power outages caused by spring failure.

Processing difficulties and solutions

However, achieving such high manufacturing standards is not easy. First, the spring material is usually special alloy steel, which has high hardness and is difficult to process; second, due to the complex structural design of the spring, including slight changes in the spiral angle and tight winding spacing, higher requirements are placed on the processing technology. In addition, thermal deformation during processing is also one of the key factors affecting the quality of the finished product.

In order to overcome the above difficulties, the customer in this case adopted advanced ultra-large multi-axis cutting machine equipment, and combined with the professional technical support provided by Zhikai CNC, successfully solved these problems. By optimizing cutting paths, adjusting processing parameters, and real-time monitoring of system status, processing efficiency and product quality are significantly improved.

Summary and Outlook

"Innovation is the driving force for the advancement of science and technology, while quality is the foundation for the survival of an enterprise." This sentence deeply reflects the importance of technological innovation and quality management in the field of smart grid equipment manufacturing, especially in the manufacturing process of components with extremely high precision requirements such as the internal contact spring of the circuit breaker. As a leader in the industry, Zhikai CNC not only focuses on technology research and development, but also is committed to providing comprehensive after-sales service to ensure that every customer can get the best support and service.

For other parts that require high-precision cutting, such as circuit boards, heat sinks, etc., Zhikai CNC also provides a variety of efficient and reliable solutions. With deep technical accumulation and continuous R&D investment, we are committed to bringing customers a more intelligent and efficient processing experience. Choosing Zhikai CNC means choosing a trustworthy professional partner. Let us work together to meet more challenges and opportunities in the future.

With strong technical strength and strict quality management, Zhikai's medium-speed wire cutting machine tools have become the first choice for many manufacturing companies, such as elevator manufacturing: key safety parts for elevator door locks, audio equipment: magnetic isolation plates in the magnetic circuit system of speakers, bridge construction: metal accessories for bridge expansion joints, rail transportation: customized production of decorative panels in subway carriages, and high-speed trains: precision parts for wheel alignment devices. Advanced CNC systems and precision processes ensure that the machine tools run smoothly and with low errors; the full after-sales service allows customers in Pishan County, Moyu County, Cele County, Minfeng County, Yutian County, Hotan County, Lop County, and Hotan City to experience meticulous support. Zhikai is willing to work with you to create efficient production and a better future. In addition, in order to help everyone better understand the relevant knowledge of medium-speed wire cutting machine tools, we will soon launch relevant popular science articles such as ZKA400 high-speed medium-speed wire cutting machine, small 1-meter wire cutting EDM, DK7735 small wire cutting EDM, C-type machine tool wire cutting EDM, DK7740 full-servo wire cutting machine, 800 high-precision medium-speed wire cutting machine, strip-type integrated wire cutting EDM, 400 super-large wire cutting, 7740 precision wire cutting EDM, etc. Everyone is welcome to visit and obtain relevant solutions.

If you have any needs, please contact Zhikai : 18013131588