Wire cutting of precision parts of high-speed train wheel alignment device

When a high-speed train is running on the rails at a speed of 350 kilometers per hour, have you ever wondered what is silently guarding every smooth ride? The answer lies in the precision parts of the wheel alignment device. The processing accuracy of these seemingly insignificant parts is directly related to the safety of train operation, and large manual machine tool wire cutting processing technology is the core process for creating them.

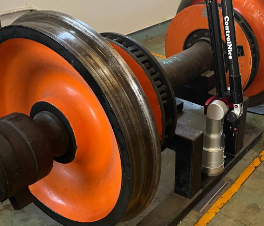

In the production of high-speed train wheel alignment devices, many key components need to be processed with the help of large manual machine tools. For example, the locating pins and guide blocks in the device have extremely high requirements for dimensional accuracy and surface finish. The locating pins must accurately match the connection holes between the car body and the bogie to ensure the rigidity and stability of the train during operation; the guide blocks must guide the wheels to maintain the correct track under complex road conditions. With flexible operation and high-precision control, large manual machine tools can control the dimensional error of these components within ≤ ±0.00 3 mm to meet the design requirements.

However, the processing of precision parts for wheel alignment devices is not an easy task. First, the material properties bring challenges. These parts are usually made of high-strength alloy steel, which has high hardness and toughness. They are difficult to cut using ordinary processing methods, and high temperatures are easily generated during the cutting process, resulting in material deformation and internal stress concentration. Second, the structure is highly complex. Some parts have irregular surfaces and tiny slot structures, which require careful planning of the cutting path. Any slight deviation will affect the function of the component. Taking the data of a certain customer as an example, when using traditional processing methods, the scrap rate of precision parts for wheel alignment devices is as high as 15%. After the introduction of large manual machine tool wire cutting processing, the scrap rate was reduced to 3%, and the product qualification rate was greatly improved.

With its strong R&D strength, Zhikai CNC continuously optimizes the performance of large manual machine tool wire cutting equipment to address these processing difficulties. Its developed equipment not only performs well in the processing of precision parts of wheel alignment devices, but also provides efficient and accurate solutions for other parts of high-speed trains, such as the cutting of heat dissipation grooves of brake discs and the forming of coupler connection parts.

What is even more trustworthy is Zhikai CNC's complete after-sales service system. From equipment installation and commissioning to operator training, from daily maintenance to emergency fault handling, Zhikai CNC's professional team always responds quickly to solve problems for customers.

What we sell is not only machine tools, but also the confidence of China's intelligent manufacturing. When you choose Zhikai, you choose the research and development strength of a national high-tech enterprise, a 2-hour emergency response network covering 138 cities, and a processing database with 3,000+ successful cases. In the near future, we will successively launch large-scale CNC medium-speed wire cutting machines, high-quality hardware spark wire cutting, micro-high-intelligent machine tool wire cutting, super-large DK wire cutting machines, DK7740dk7763 wire cutting machine equipment, DK7740 high-speed metal wire cutting machine, DK7735 precision machine tool wire cutting, ZKA400 four-axis cutting equipment, 2-meter four-axis metal wire cutting machine and other related popular science articles. Welcome everyone to visit and obtain relevant solutions. Friends from Youxi County, Sanyuan District, Mingxi County, Yong'an City, Jianning County, Taining County, Jiangle County, Qingliu County, Datian County, Ninghua County, Shaxian District and other places are welcome to inquire about prices.

If you have any needs, please contact Zhikai: 18013131588