C-type automatic wire-cut EDM machine tool for high-precision subway vehicle component processing

In the manufacturing stage of precision components for subway vehicles, how does the C-type automatic wire-cut EDM machine perform a perfect symphony of precision and efficiency? Let us explore the miracle of the application of this advanced technology in the field of rail transportation.

The high-precision components of subway vehicles are the core to ensure the safe and comfortable operation of the subway. On the production line of a certain rail transit company, the C-type automatic wire-cut EDM machine tool has become an important weapon to improve the precision of components. The following are the processing difficulties of several key components and the application advantages of the C-type automatic wire-cut machine tool:

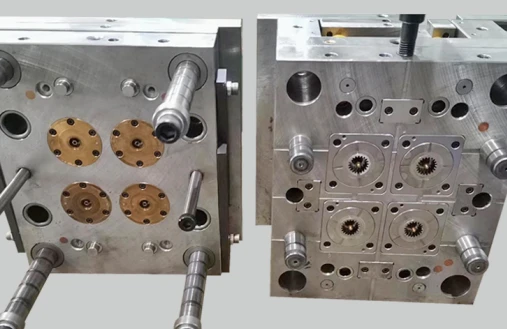

Gear precision mold: The gear mold of subway vehicles requires extremely high precision and surface quality. The difficulty in processing lies in the complex shape and tiny dimensional tolerance of the mold. The C-type automatic wire cutting EDM machine tool achieves precise mold processing with its high precision and high stability.

Bearing seat: The difficulty in processing the bearing seat lies in the complexity of its internal structure and the hardness of the material. The C-type automatic wire cutting machine ensures the processing quality and dimensional consistency of the bearing seat through its precise control system.

Product analysis of case customers:

Through the analysis of a rail transit company's products, we found that the high-precision components of subway vehicles processed by C-type automatic wire-cut EDM machines not only reached the industry-leading level in dimensional accuracy and shape complexity, but also significantly improved production efficiency. Data shows that the qualification rate of components processed by this machine tool reached 99.8%, and production efficiency increased by 30%.

Viewpoint:

The application of C-type automatic wire-cut EDM machine tools in the processing of high-precision components for subway vehicles not only improves product quality and production efficiency, but also brings significant economic benefits to the enterprise. This fully demonstrates the important role of advanced manufacturing technology in promoting the rail transit industry.

Summary:

Zhikai CNC uses technology to create quality and service to win trust. "In the field of rail transit, Zhikai CNC is not only good at processing high-precision components for subway vehicles, but also can provide professional cutting solutions for other complex parts.

We are well aware that focusing on research and development and improving after-sales service are the keys to Zhikai CNC's success in the market. In the future, Zhikai CNC will continue to be committed to technological innovation and provide customers with a more efficient and stable cutting experience.

Zhikai CNC, precise cutting, escorts rail transit.