Key application of 1 meter four-axis cutting machine tool in the manufacturing of speaker magnetic circuit precision parts

In the field of high-end audio equipment manufacturing, the purity and stability of sound quality often depend on the processing accuracy of core components. Among them, the precision parts of the speaker magnetic circuit system, as key components affecting acoustic performance, have extremely high requirements for dimensional accuracy and surface finish. Traditional processing methods are difficult to meet the cutting needs of complex structures, and the 1-meter four-axis cutting machine tool is becoming the preferred equipment for industry-leading companies with its large travel, high precision and multi-angle cutting capabilities.

This article will take a well-known audio equipment company as an example to analyze the application of a 1-meter four-axis line cutting machine in the processing of precision parts and other core components of the speaker magnetic circuit system, and explore its technical difficulties and Zhikai CNC's innovative solutions.

Case analysis: Application of 1-meter four-axis cutting machine tool in the processing of key parts of audio equipment

1. Precision parts of the loudspeaker magnetic circuit system - challenges of high precision and complex structure

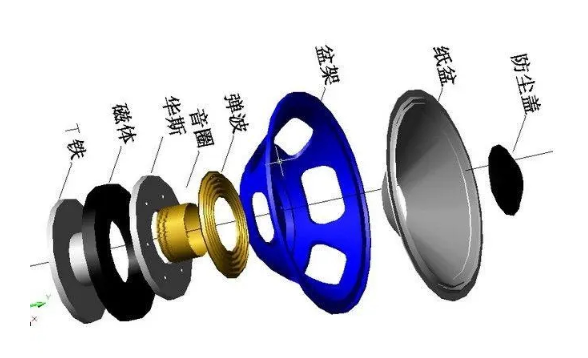

The speaker magnetic circuit system consists of magnetic plates, magnetic steel, pole cores and other components. Its function is to form a uniform magnetic field to ensure the linear movement of the voice coil, thus affecting the sound quality. These parts are usually made of high-permeability alloys or neodymium iron boron magnetic materials, and face the following difficulties during processing:

The material is hard and brittle, and is prone to cracking during traditional processing: NdFeB magnets are hard but brittle, and mechanical cutting can easily produce microcracks, affecting their magnetic properties.

Difficulty in processing special-shaped structures: Magnetic plates usually have complex curves and bevels, and ordinary wire cutting machines are difficult to achieve high-precision multi-angle cutting.

Strict dimensional tolerance ( ≤±0.00 3 mm): The assembly gap between the parts of the magnetic circuit system is extremely small, and insufficient precision will lead to uneven magnetic field and distortion.

Solution for 1 meter 4-axis cutting machine:

Four-axis linkage technology supports tilted cutting (±30°) to meet the needs of bevel processing of magnetic conductive plates.

Adaptive discharge parameter adjustment optimizes energy output for different magnetic materials, reduces heat-affected zones, and avoids degradation of material performance.

The long stroke (1 meter) design enables processing of large magnetic circuit components at one time, reducing splicing errors.

After adopting Zhikai CNC's 1-meter four-axis cutting machine, the audio equipment company increased the processing efficiency of magnetic circuit parts by 40%, reduced the defective rate to below 0.5%, and significantly improved the consistency of the speaker frequency response curve.

2. Processing and application of other key components

In addition to the magnetic circuit system, the 1-meter four-axis cutting machine is also widely used in the following core components of audio equipment:

Speaker frame mold: Ultra-thin aluminum alloy (0.3-0.8mm) precision cutting, no burrs and no deformation.

Horn tweeter: A titanium alloy component with a complex curved surface, which must ensure the smoothness of the sound wave reflection surface (Ra ≤ 0.7-1.4 μm).

Crossover heat sink: Multi-hole array structure, traditional stamping is easy to deform, wire cutting can ensure the accuracy of hole position.

Zhikai CNC: Defining industry standards with technological innovation and ultimate service

As a leading brand of high-end CNC machine tools in China, Zhikai CNC's 1-meter four-axis cutting machine tool has become a strategic partner of audio manufacturing companies with its three core advantages:

Self-developed intelligent control system: integrated AI parameter optimization module, automatically matches material properties, and realizes "one-click" high-precision processing.

Industry customized solutions: We provide exclusive process database for special parts such as speaker magnetic circuits and titanium film tweeters.

All-weather service guarantee system: 48-hour fault response, quarterly preventive maintenance, and remote diagnosis support to ensure zero downtime of customers' production lines.

Summarize

"In the world of acoustic precision, a precision difference of 0.01 mm is the dividing line between heavenly sound and noise."

For audio equipment manufacturers, choosing Zhikai four-axis cutting machine is not only a pursuit of precision, but also a shaping of the brand's acoustic genes. We strive for the ultimate in every micron to achieve the pure original sound of each speaker.

Zhikai's medium-speed wire cutting machine tools have won the trust of customers with their excellent processing accuracy and stable performance. Strict process control and advanced slow wire cutting function systems ensure the efficient operation of 630 wire cutting machine tools, strip-type three-axis EDM wire cutting machines, 400c wire cutting machines, 630 high-precision wire cutting machines, DK7740t wire cutting machines, 500 multi-axis wire cutting machines, DK7740 mirror metal wire cutting machines, ZKA400 large swing medium-speed wire cutting machines and other equipment. At the same time, the whole-process considerate after-sales service allows customers in Pingba District, Zhenning County, Ziyun County, Puding County, Guanling County, Xixiu District and other places to have no worries. Choosing Zhikai means choosing a partner who attaches equal importance to quality and strength, and moving towards the brilliant future of intelligent manufacturing together. In the near future, we will successively launch popular science articles on 630 wire cutting machine, strip-type three-axis EDM wire cutting machine, 400c wire cutting machine, 630 high-precision wire cutting machine, DK7740t wire cutting machine, 500 multi-axis wire cutting machine, DK7740 mirror metal wire cutting machine, ZKA400 large swing wire cutting machine, etc. Welcome everyone to visit and obtain relevant solutions.

If you have any needs, please contact Zhikai : 18013131588