Application of 400-type wire cutting machine tool to process laser internal reflector frame in laser equipment

In the field of laser technology that pursues extreme precision and stability, every detail is crucial. Are you curious about how the key components inside those high-precision laser equipment are accurately manufactured? Today, we will explore how the 400 precision wire cutting machine tool can help make the reflector frame inside the laser and unveil the mystery of this high-tech manufacturing process.

Case Study: Challenges and Solutions in Manufacturing Laser Internal Reflector Frames

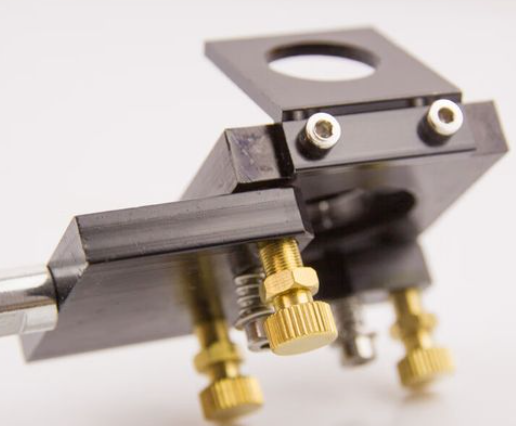

As a crucial component of laser equipment, the internal reflector frame of the laser is used to ensure that the laser beam can be accurately transmitted and focused with minimal energy loss. Such components usually need to have extremely high dimensional accuracy and surface finish, and also need to meet strict material requirements, such as high temperature resistance and oxidation resistance. For example, in some high-performance laser equipment, the error range of the reflector frame needs to be controlled within ≤±0.00 3 mm, which places very high demands on the processing equipment.

The 400 precision wire cutting machine is an ideal choice for solving this problem due to its excellent processing performance. It can not only achieve ultra-high processing accuracy at the sub-millimeter level, but also ensure a surface roughness of Ra ≤ 0.7-1.4 μm, greatly improving the quality and stability of the reflector frame. Especially when dealing with complex shapes and fine structures, the 400 precision wire cutting machine effectively solves processing difficulties such as large deformation and easy cracking by optimizing the cutting path and parameter settings. In addition, in response to the processing needs of different materials (such as copper alloys, aluminum alloys, etc.), the machine also provides a variety of cutting modes to further improve production efficiency and finished product quality.

Data support and industry perspectives

According to actual application data, after using the 400 precision wire cutting machine to produce the internal reflector frame of the laser, the qualification rate of related products has increased by about 30%, significantly reducing the rework costs caused by quality problems. At the same time, due to its efficient processing speed and low material loss rate, it brings considerable economic benefits to production companies. Industry experts believe that with the continuous development of laser technology, the demand for high-quality reflector frames will continue to increase, and the application prospects of 400 precision wire cutting machine tools will also be broader.

Summary and Outlook

"Precision determines success or failure" is not only a high-level summary of the value of the 400 precision wire cutting machine, but also the development concept that Zhikai CNC has always adhered to. In addition to the successful application on the internal reflector frame of the laser, Zhikai CNC is also committed to providing customized cutting solutions for other laser equipment, such as laser head housing, optical platform, etc. We always attach importance to R&D investment, continuously explore new technologies, and strive to create greater value for customers.

It is worth mentioning that Zhikai CNC not only has advanced technical strength, but also pays more attention to the quality of after-sales service. Our professional team is on call at any time to ensure that every customer can enjoy the most considerate service. "Choosing Zhikai means choosing trust and peace of mind." Let us work together to open a new chapter of intelligent manufacturing!

In summary, the 400 precision wire cutting machine tool plays an irreplaceable role in the production process of the laser internal reflector frame. It not only improves the quality and reliability of the product, but also promotes the progress and development of the entire industry. I hope this article can provide valuable reference information for the majority of peers and jointly promote the manufacturing industry to a higher level.

Zhikai CNC has 20 years of R&D and manufacturing experience as a manufacturer of medium-speed wire cutting machine tools and a professional slow-speed wire cutting system solution provider. Its products are widely used in printing machinery: paper guide devices for high-speed printing machines, leather processing machinery: high-precision edges of leather cutting knives, household appliances: precision cutting of induction cooker panels, communication equipment: precision parts of optical fiber connectors. The projects are spread across Yindu District, Wenfeng District, Beiguan District, Neihuang County, Long'an District, Linzhou City, Tangyin County, Anyang County, Hua County and other cities. In addition, in order to facilitate everyone to better understand the relevant knowledge of medium-speed wire cutting machine tools, we will soon launch 2.5-meter split wire cutting equipment, 500 micro wire cutting machine equipment, large automatic CNC wire cutting, 2-meter fully enclosed medium-speed wire cutting machine, T-type wire cutting EDM wire cutting machine, ZKA400 titanium alloy wire cutting EDM, DK7735 hardware medium-speed wire cutting machine, DK7735 mold machine tool wire cutting and other related popular science articles. Welcome everyone to visit and obtain relevant solutions.

If you have any needs, please contact Zhikai : 18013131588