Curtain wall precision manufacturing: C-type wire cutting innovates aluminum alloy frame joint processing

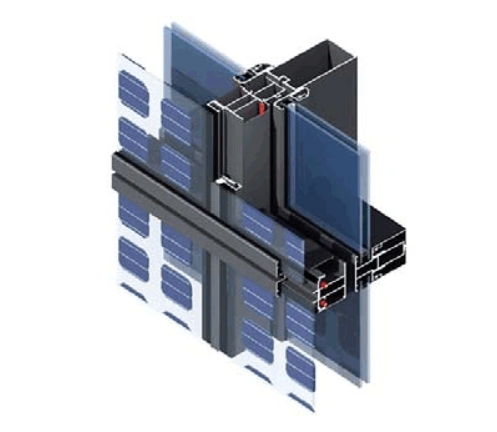

Under the dazzling coat of modern buildings, there are countless precision components silently supporting them. Among them, the building curtain wall system has become an indispensable part of modern architectural design with its beautiful, energy-saving and safe characteristics. As the skeleton of the curtain wall system, the precision and stability of the aluminum alloy frame directly affect the quality of the entire curtain wall. Today, we will unveil the mystery of precision cutting of aluminum alloy frame joints and see how C-type high-performance wire cutting machine tools can show their prowess in this field.

Case Customer Product Analysis

Our case client, a leading building curtain wall system company in the industry, is known for its high quality and strict precision requirements. In their production process, many key components rely on C-type high-performance wire cutting machine tools for precision processing. These parts mainly include:

Aluminum alloy frame joint: As the core component connecting aluminum alloy profiles, the accuracy of the frame joint directly determines the overall flatness and stability of the curtain wall. Traditional processing methods are difficult to meet the requirements of high precision and high efficiency, while C-type wire cutting machines can achieve micron-level processing accuracy, ensuring a perfect fit between the joint and the profile.

Special-shaped support parts: Modern building curtain walls are often complex in design and contain a large number of special-shaped structures. These special-shaped support parts are extremely difficult to process and require the equipment to have extremely high flexibility and precision. The C-type wire cutting machine's numerical control system and multi-axis linkage function can easily realize the processing of various complex curved surfaces and special-shaped holes.

Decorative strips and inserts: Although these parts do not directly bear structural forces, their precision and aesthetics are equally important. C-type wire cutting machines can ensure the perfect docking of decorative strips and profiles, as well as the precise assembly of inserts and profiles, thus improving the overall visual effect of the curtain wall.

Processing difficulties and advantages of C-type wire cutting

The processing of the above parts faces many challenges:

High precision requirements: Building curtain walls have extremely high precision requirements for components, usually reaching ≤±0.00 3 mm or even higher. Traditional processing methods, such as milling and drilling, are difficult to meet such stringent precision requirements and are prone to error accumulation, resulting in unevenness and large gaps after curtain wall installation.

Complex structure processing: The design of modern building curtain walls is becoming more and more diverse, and the structure of parts is becoming more and more complex. Traditional processing equipment is difficult to cope with the processing needs of various special-shaped surfaces and complex hole systems.

Material property challenges: Although aluminum alloy materials have the advantages of light weight and high strength, they also have processing difficulties such as easy deformation and burning. Traditional processing methods are prone to produce stress deformation and surface burns during the processing, affecting the strength and appearance of parts.

Efficiency and cost: While ensuring accuracy, improving processing efficiency and reducing production costs are also important issues facing the curtain wall industry. Traditional processing methods are inefficient, have high labor costs, and are difficult to meet the needs of large-scale production.

The C-type high-performance wire-cutting machine tool equipment is designed to address these difficulties. It has the following significant advantages:

Ultra-high processing accuracy: The C-type wire cutting machine adopts advanced CNC system and precision transmission mechanism, which can achieve positioning accuracy of ≤±0.00 6 mm and repeat positioning accuracy of ≤±0.00 3 mm, fully meeting the precision requirements of the curtain wall industry for parts.

Powerful complex structure processing capability: The multi-axis linkage function of the C-type wire cutting machine can easily realize the processing of various complex curved surfaces and special-shaped holes, meeting the processing needs of various complex designs.

Excellent material adaptability: The C-type wire cutting machine adopts the principle of electro-erosion processing, avoiding the stress deformation and surface burn problems caused by direct contact between the tool and the workpiece in traditional processing methods. It is particularly suitable for processing easily deformed materials such as aluminum alloys.

High efficiency and low cost: C-type wire cutting machine has a high degree of automation, and can complete multiple processes in one clamping, which greatly improves the processing efficiency and reduces labor costs. At the same time, electro-erosion processing has almost no tool loss, which also reduces processing costs.

Data and opinions

According to the actual production data of the case customer, after using C-type high-performance wire cutting machine equipment to process aluminum alloy frame joints, its processing accuracy has increased by more than 50%, production efficiency has increased by 30%, and the product qualification rate has reached more than 99.5%. At the same time, due to the improvement of processing accuracy, the installation efficiency of the curtain wall has also been greatly improved, and the installation error has been reduced by more than 80%.

"In the past, our biggest headache was the accuracy of the frame joints. The slightest error would make installation time-consuming and labor-intensive, and also affect the appearance. Now that we have used the C-type wire cutting machine, these problems have been solved. The accuracy is higher, the installation is faster, and customer satisfaction has also increased." The production supervisor of the case customer commented.

Summary and Outlook

The application of C-type high-performance wire cutting machine tools in the processing of building curtain wall system parts is an innovation in technology and process. With its excellent precision, efficiency and reliability, it provides strong support for the high-quality development of the curtain wall industry. "Precision manufacturing, extraordinary achievements" is the true portrayal of C-type wire cutting machine tools in the curtain wall industry.

In addition to aluminum alloy frame joints, Zhikai CNC's C-type wire cutting machine equipment is also widely used in the precision processing of other parts in the curtain wall industry, such as:

Precision cutting of aluminum alloy profiles: It can achieve cutting of profiles at any angle and in complex shapes to meet various design requirements.

Processing of steel parts: For steel parts used in curtain wall systems, C-type wire cutting machines can also achieve high-precision and high-efficiency processing.

Zhikai CNC always insists on R&D-driven, continuously invests a lot of resources in technological innovation and product upgrades, and is committed to providing customers with more advanced and reliable C-type wire cutting machine equipment. We have an experienced R&D team and a complete after-sales service system, and can provide customers with a full range of technical support and solutions. Choosing Zhikai CNC means choosing professionalism, choosing peace of mind, and choosing the future! We believe that with the help of Zhikai CNC, the building curtain wall industry will usher in a better tomorrow!

From precision molds to complex parts processing, Zhikai CNC's medium-speed wire cutting machine tools redefine the industry benchmark with a precision standard of ≤ ±0.003 mm. We are well aware that each device is the core combat power of your production line, so we not only provide machine tools, but also provide full-link empowerment from process debugging to personnel training. If you are looking for a hard-core partner who can improve processing efficiency by 30%, contact the official website of [Zhikai CNC] to get exclusive technical solutions immediately - let Zhikai use 20 years of cutting technology to provide confidence for your capacity upgrade. "In the near future, we will successively launch F-type large swing wire cutting equipment, 500f-type wire cutting machine, Pin-type four-axis spark wire cutting, 1-meter high workpiece spark wire cutting, 2-meter stepper metal wire cutting machine, Pin-type aluminum alloy wire cutting equipment, Pin-type heavy-duty wire cutting machine, DK77352-meter machine tool wire cutting and other related popular science articles. Everyone is welcome to visit and obtain relevant solutions.

If you have any needs, please contact Zhikai : 18013131588