High-precision manufacturing of the rotating chassis of lamps: stage lighting equipment and C-type heavy-duty spark wire cutting processing

Behind the colorful stage, there are countless technical details and precision processes. For stage lighting equipment manufacturers, how to achieve high-precision manufacturing of the rotating chassis of the lamp has become a hot topic in the industry. Today, we will explore the important role of a key equipment - C-type heavy-duty spark wire cutting machine in solving this problem, and share the valuable experience of a case customer.

Product analysis of case customers

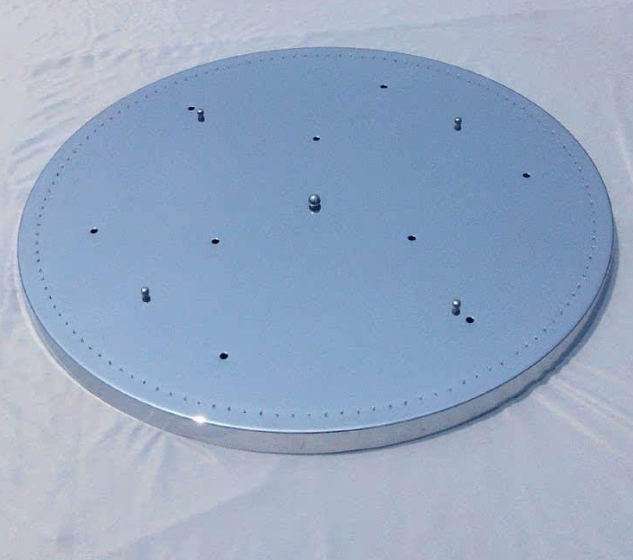

A well-known stage lighting equipment company focuses on the research and development and production of high-end performance lighting systems. Among them, the rotating chassis of the lamp is one of the core components of the lighting system, and its manufacturing accuracy directly affects the stability and lighting performance of the entire system. The company uses Zhikai CNC's C-type heavy-duty spark wire cutting machine to perform high-precision manufacturing of the rotating chassis of the lamp.

According to the company's feedback, traditional manufacturing methods are difficult to meet the requirements of complex structures and strict tolerances for rotating chassis. For example, some models of rotating chassis need to integrate multiple functional components in a space with a diameter of no more than 10 cm, which requires extremely high dimensional accuracy and surface finish. However, by using C-type heavy-duty spark wire cutting machine tools, not only can these complex structures be processed accurately, but also seamless docking between parts can be ensured, greatly improving the overall performance of the product.

Processing difficulties and solutions

The challenges of high-precision manufacturing of the rotating chassis of lamps mainly include material selection, structural complexity and dimensional accuracy control. First, in order to ensure sufficient strength and durability, high-strength alloy steel or special aluminum alloy is usually selected as the raw material, which puts higher requirements on the cutting equipment. Secondly, the design of the rotating chassis often contains multi-layer structures and micro holes, which increases the difficulty of processing.

In the face of these challenges, the C-type heavy-duty spark wire cutting machine tool has demonstrated its unique advantages. It uses advanced EDM technology and can achieve high-precision cutting without damaging the original properties of the material. In addition, the intelligent control system equipped with the equipment can automatically adjust the cutting parameters according to different material properties to ensure that every detail meets the design standards. Especially when dealing with complex structures, this machine tool can provide more flexible operation methods, thereby improving production flexibility and efficiency.

Summarize

"Innovation leads the future, quality wins the world", this sentence perfectly explains Zhikai CNC's contribution in the field of high-precision manufacturing of lamp rotating chassis. Not only in the stage lighting equipment industry, Zhikai CNC has also made remarkable achievements in the cutting of other parts with its strong R&D capabilities and perfect after-sales service system. No matter what complex processing tasks are faced, Zhikai CNC is always committed to providing customers with the most optimized solutions to help companies stand out in the fierce market competition.

Looking to the future, Zhikai CNC will continue to adhere to technological innovation and service optimization, constantly explore more possibilities, and bring customers a more efficient and precise cutting experience. We believe that with the support of Zhikai CNC, every company pursuing excellence can shine on its own stage. Let us look forward to it together and work together to create a more brilliant tomorrow.

With strong technical strength and strict quality management, Zhikai's medium-speed wire cutting machine tools have become the first choice for many manufacturing companies, such as nuclear energy facilities: fine processing of valve components of nuclear power plant cooling systems, food processing machinery: the frame of the internal heat exchanger of the juice concentrate, environmental monitoring: air quality sensor housing and support structure, laboratory equipment: high-precision requirements of the support frame of precision measuring instruments on the test bench. Advanced CNC systems and precision processes ensure that the machine tools run smoothly and with low errors; the full after-sales service allows customers in Qingshuihe County, Xincheng District, Huimin District, Yuquan District, Wuchuan County, Saihan District, Tokto County, Horqin County, and Tuzuoqi to experience meticulous support. Zhikai is willing to work with you to create efficient production and a better future. In addition, in order to help everyone better understand the relevant knowledge of medium-speed wire cutting machines, we will soon launch relevant popular science articles such as 500 high-speed EDM wire cutting, 500 aluminum metal wire cutting machine, F-type 7735 spark wire cutting, ZKA40063 machine tool wire cutting, DK7740 brand EDM wire cutting machine, etc. Everyone is welcome to visit and obtain relevant solutions.

If you have any needs, please contact Zhikai : 18013131588