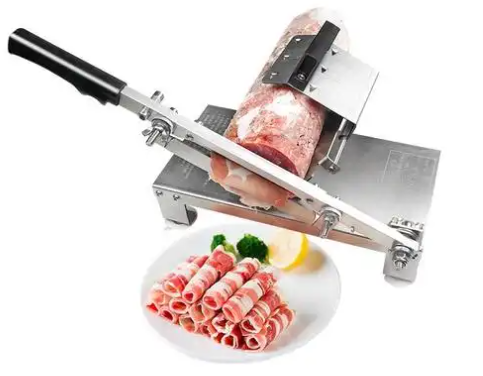

Slicer tool processing: food machinery and C-type fully enclosed wire cutting equipment

In the food processing industry, the precise operation of the slicer knife is behind a piece of accurately cut food. The processing accuracy of the complex shape of the slicer knife directly affects the cutting efficiency, finished product quality and equipment life of the food. Facing this key link, the C-type fully enclosed wire cutting equipment is becoming a powerful assistant for food processing machinery manufacturers with its unique advantages.

Take a food processing machinery company as an example. In the production process of slicer knives, C-type fully enclosed wire cutting equipment undertakes the core processing tasks. Slicer knives need to have sharp cutting edges and complex geometric shapes to meet the cutting requirements of different foods, such as uniform slicing of meat, fine shredding of fruits and vegetables, etc. The angle, thickness of the cutting edge and the special-shaped contour of the blade all require extremely high processing precision. When processing complex shapes, traditional processing methods are not only inefficient, but also difficult to ensure accuracy. Problems such as blunt cutting edges and shape deviations are prone to occur, affecting tool performance and food processing effects.

The C-type fully enclosed wire cutting equipment demonstrates its powerful capabilities here. Its fully enclosed design effectively isolates the coolant, debris, etc. generated during the processing process, which not only ensures the cleanliness of the processing environment, but also avoids the interference of external factors on the processing accuracy. The equipment can accurately control the movement trajectory of the electrode wire through a high-precision CNC system to achieve micron-level cutting accuracy. In the processing of complex shapes of slicer tools, whether it is a tiny sawtooth structure or an irregular curved surface contour, the C-type fully enclosed wire cutting equipment can easily cope with it, controlling the dimensional error of the tool edge within ±0.01mm, and the surface roughness reaches Ra≤0.7-1.4μm, ensuring that the tool is sharp and durable.

However, it is not easy to process the complex shapes of slicer cutters. Cutters are usually made of high-hardness alloy materials to ensure wear resistance and cutting performance, but this also increases the difficulty of processing. During the cutting process, high-hardness materials tend to cause faster electrode wire loss, and the high temperature generated by processing may cause thermal deformation of the cutter material, affecting the accuracy. In addition, the complex shape of the cutter has extremely high requirements for programming and operation, and the slightest carelessness may lead to processing errors.

Zhikai CNC continues to increase its R&D investment to address these difficulties. The intelligent electrode wire loss compensation technology developed can monitor the electrode wire status in real time and automatically adjust the parameters, reducing the electrode wire loss by 30% and effectively extending the service life; the innovative temperature control system can accurately control the processing temperature and reduce the risk of thermal deformation of the tool. At the same time, Zhikai CNC is also equipped with a simple and efficient programming system that supports the import of 3D models and generates the optimal cutting path through intelligent algorithms, reducing the difficulty of operation and improving processing efficiency.

With strong technical strength and strict quality management, Zhikai medium-speed wire cutting machine tools have become the first choice for many manufacturing companies, such as drone manufacturing: precision parts for drone camera stabilization gimbals, railway signal lights: railway signal light hoods, refrigeration equipment: precision cutting of air-conditioning compressor valves, marine engineering equipment: anchor chain rings for offshore oil drilling platforms, industrial waste gas purification equipment: electrostatic precipitator electrode plates, etc. Advanced CNC systems and precision processes ensure that the machine tools run smoothly and with low errors; the full after-sales service allows customers in Yangshan County, Qingxin District, Liannan County, Yingde City, Lianzhou City, Lianshan County, Fogang County, and Qingcheng District to experience meticulous support. Zhikai is willing to work with you to create efficient production and a better future. In addition, in order to help everyone better understand the relevant knowledge of medium-speed wire cutting machines, we will soon launch relevant popular science articles such as DK7740 large swing medium-speed wire cutting machine, 1-meter large swing spark wire cutting, 630 servo wire cutting machine equipment, 630 precision machine tool wire cutting, DK7740 large taper metal wire cutting machine, DK7732 1-meter wire cutting machine, F-type high-end EDM wire cutting, T-type high-end spark wire cutting, 7740 split wire cutting machine, etc. Welcome to visit and obtain relevant solutions.

If you encounter difficulties in the processing of food processing machinery parts, please contact Zhikai: 18013131588, and let us use our professional technology to escort your production.