Electric vehicle battery connector, precision method of large mold wire cutting equipment

In the booming electric vehicle industry, battery performance and safety have become the core of competition. As the "nerve hub" that ensures the stable operation of the battery, the processing accuracy of the internal connectors of the battery management system directly affects the performance of the entire vehicle. How to overcome the connector processing difficulties? Large-scale mold wire cutting equipment provides a professional answer.

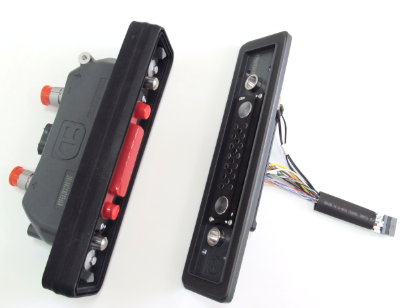

Take a certain electric vehicle battery manufacturer as an example. Although the internal connectors of its battery management system are small in size, they undertake complex signal transmission and power distribution tasks. Such connectors usually use copper alloys or stainless steel materials with high conductivity and high wear resistance to ensure stable operation under complex working conditions. However, the characteristics of these materials also bring many challenges to processing. From the perspective of dimensional accuracy, the pin hole diameter tolerance of the connector must be strictly controlled within ≤ ±0.00 3 mm, otherwise there will be problems such as poor contact and excessive resistance, which will affect battery performance; in terms of structural design, the connector contains a large number of micro-cavities and thin-walled structures, with the thinnest wall thickness of only 0.15mm. Traditional processing methods can easily cause thin-wall deformation and cavity cracking, which cannot meet the assembly and use requirements of the product. At the same time, the roughness requirements of the connector surface are extremely high. If there are tiny burrs or scratches on the surface, it may cause partial discharge and bury safety hazards.

Large-scale mold wire cutting equipment has shown significant advantages in dealing with these challenges. The equipment uses the principle of electric spark discharge and accurately controls the movement trajectory of the electrode wire through the CNC system, which can achieve high-precision processing of complex-shaped connectors. When processing the connectors in the above case, the large-scale mold wire cutting equipment can stably control the pin aperture error to ≤ ±0.003mm with its micron-level positioning accuracy, far exceeding the industry standard. In addition, since wire cutting is a non-contact processing and there is no cutting force, it can perfectly protect the thin-walled structure and micro-cavity of the connector, so that parts with a wall thickness of only 0.15mm can also be fully formed. In addition, the equipment can also control the surface roughness Ra value of the connector to ≤ 0.7-1.4 μm by optimizing the discharge parameters , effectively avoiding the risk of partial discharge.

Zhikai CNC has been deeply engaged in the field of large-scale mold wire cutting equipment for many years, and has always regarded research and development and innovation as the core of development. The company invests a lot of money in technology research and development every year, and has formed a professional team to overcome technical difficulties such as electrode wire tension control and pulse power supply optimization, and continuously improve the processing accuracy and stability of the equipment. In terms of after-sales service, Zhikai CNC has established a rapid response mechanism, and professional technicians are online 24 hours a day, 7 days a week, and can promptly solve various problems in the use of equipment for customers, from installation and commissioning to daily maintenance, providing considerate services throughout the process. In addition to the internal connectors of the battery management system, Zhikai CNC's large-scale mold wire cutting equipment also performs well in the processing of parts such as electrode molds and heat dissipation structures of electric vehicle batteries, and can provide customers with customized cutting solutions for the entire process.

Zhikai's medium-speed wire cutting machine is known for its ultra-high precision and excellent stability. Relying on core technologies such as the self-developed slow wire cutting system and primary color processing high-frequency power supply, it provides customers with low-energy consumption and high-efficiency processing solutions. Comprehensive after-sales support and customized services ensure that every user can experience safe and reliable equipment performance. Zhikai interprets quality with strength. A variety of machine tools such as: Pin-shaped wire cutting wire cutting machine equipment, large-scale high-intelligence wire cutting machine equipment, Pin-shaped high-efficiency wire cutting EDM, ZKA400 split wire cutting EDM, 2.5 meters brand wire cutting EDM, DK7732 precision machine tool wire cutting, ZKA400 aluminum alloy spark wire cutting, DK7740 stepping wire cutting machine, T-shaped wire cutting machine CNC wire cutting have injected strong power into the transformation and upgrading of industries such as outdoor sports equipment: trekking pole adjustment buckle, railway signal system: track circuit detection equipment shell, jewelry: realization and optimization of complex design of precious metal jewelry, ceramic production: high-temperature resistant metal parts inside ceramic sintering furnace.

If you are troubled by the problem of parts processing, please contact Zhikai: 18013131588. Join hands with Zhikai to open a new chapter in the precision manufacturing of electric vehicle batteries.